The first in th world (any-fuel) home power station VTES:

- provides private houses with "green" electricity and heating

- runs on any biofuel (including solid ones: wood, pellets etc.)

- is powered by the innovative steam engine

contacts:

VKontakte

When operating during the heating season (winter), the VTES operates as a cogeneration unit (CHP). This means that VTES generates both electricity and useful heat (for heating) at the same time, in one working process. This principle of operation, called "cogeneration", is very useful for the purposes of energy conservation and environmental improvement. The following is a discussion of cogeneration in more detail.

About cogeneration

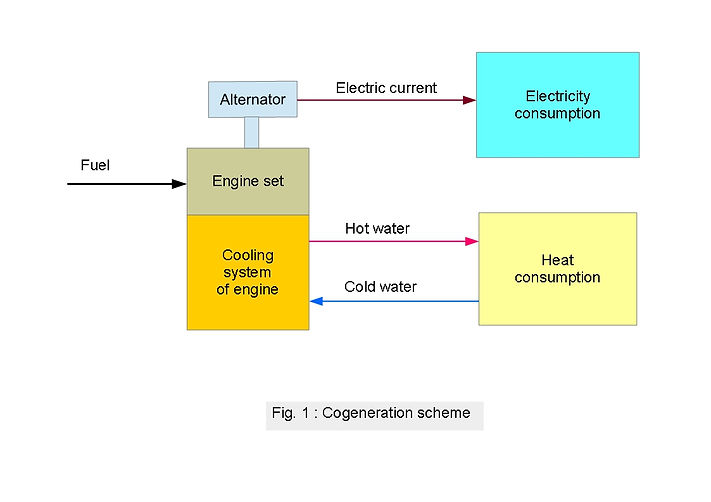

Cogeneration is the combined production of electricity and thermal energy (CHP). In fact, any production of electric energy is followed by release of heat. And the most commonly used methods of power generation – using combustion of hydrocarbons in boilers of power plants or engine generators - have an efficiency for electricity from 15 to 45% depending on design. Therefore the largest share of energy produced by the combustion of the fuel is released as heat. So the one of the major source of energy saving and resource saving is the use of cogeneration in all areas of production of electric and thermal energy, where it is possible technically and economically. In Fig. 1 you can see a diagram of cogeneration, its main elements and flows of energy between them.

To put it simply, the main point of home cogeneration is to use the heat generated by the engine of the cogeneration unit for heating and hot water supply of the house. At the same time, the engine drives a generator that generates electricity for the home. Such an installation consumes 30-35% less fuel than its total consumption by a domestic heating boiler and an external remote power plant (which dumps heat from generating electricity for the house into the atmosphere). Below in Fig. 2 shows two energy supply schemes for a private house and shows the increase in energy efficiency when using cogeneration instead of separate supply of heat and electricity.

There are huge CHP power plants operating in cogeneration mode in large cities, which provide electricity and heat for all connected consumers: apartment buildings, industrial enterprises, various institutions. That power plants use gas and steam turbines running on gas, coal or oil. Usually the individual capacity of such a turbine is not less than 50 MW and, by various technical and economic reasons, a smaller turbine capacity is quite rarely used for the purposes of cogeneration, although various manufacturers offer CHP micro-turbine plants with a electric power of 30 KW and above.

Much more frequently, if some organization needs its own energy production, it selects the gas-piston units (GPU). Typically, the GPU is used to generate the required electricity for enterprises, and sometimes the released heat is utilized in some useful process like heating, that is for cogeneration purpose. Again, on techno-economic indicators, the ordinary GPU power unit capacity is usually not less than 100 KW (for electric power). Below this limit the use of gas-piston engines for CHP is considered inefficient and unprofitable.

If we consider the household sector, that is, combined production of heat and electricity in private houses, today the small cogeneration plants (CHP units) with electric power from 1 to 5 KW are not available in the Russian market . In Western countries there are attempts of introduction of small cogeneration units (or CHP) based on gas internal combustion and Stirling engines and fuel cells. But, for various technical and economic reasons, widespread distribution of small CHP units is not occurred.

As a result to heat private houses almost everywhere homeowners use ordinary heat boilers which burn fuel. And the electricity for the households receive from the outer large power plants. That plants can not pass the pipes with hot water to each individual house in small towns and villages. So the heat, generated from electricity production for the private sector, power plants uselessly dissipate into the atmosphere. On the other hand, many private households use gasoline or diesel generator (without CHP system) to produce electricity for home needs. In this case the heat generated (up to 75% of the energy content of fuel) is uselessly discharged outside by the cooling system of the engine too. In addition to high fuel costs, disadvantages of such electricity generators are expressed in the forms of increased noise from the engine, air pollution and the need for constant supervision for replenishment of fuel, adding oil, control, etc.

The same pattern is observed in the area of energy supply for small enterprises and social facilities, with the only difference in the size of the electricity and heat consumption. If there is need to ensure the heating capacity of 30-300 kW, usual choice is to apply heating boilers wich burn gas, coal, pellet, etc. As for electricity it remains to arrange the external power supply or to install power generators working on liquid fuel (diesel or gasoline). All the disadvantages of such solutions remain the same as those for the private sector.

It is worth mentioning that the advantage of cogeneration is not limited to the described above energy savings. If we consider the whole route of delivery of electricity from large power plants to the private consumer, then that path is sometimes hundreds or thousands of miles, passing along the way in forms of various wires and cables, using a multi-step conversion of electricity into different voltages, eventually leading to substantial losses by heating the conductors and by work of the transmission devices in the transmission of electricity. Ultimately, all this leads to significant energy loss - up to 30% of the amount produced by the power plant. In the case of cogeneration such losses are reduced to almost zero.

We should also mention the possibility of using renewable energy sources as an alternative to the development of cogeneration. Of course, any source of energy alternative to burning fossil fuels is preferable. But if we consider the problem of house heating along with production of electricity, the choice is sharply narrowed. Yes, solar panels can provide household electricity, and solar collectors — hot water, but make the sun the main source of energy is possible only in the southern regions where there is a good daily insolation during the year. And there remains the problem of the impermanence of lighting due to the weather and change of day/night that you can solve only by very costly installation of a powerful battery and a massive buffer heat tank. If we consider microgeneration, there are very few geographical regions where the wind resource is sufficient to cover the energy needs of the households with the installation of a local wind turbine. And we should remember that wind electricity supply will also need costly batteries for periods of calm weather. Beyond that, local wind turbine would solve only the problem of electricity supply, so the issue of house heating remains open.

If we consider such resource of renewable energy as biofuels, in this case cogeneration becomes the preferred solution. In fact, the combustion of biofuels in cogeneration mode uses the energy contained in most full extent. The only drawback in this case is that the CHP unit for bio-fuel will be fundamentally different from existing methods of using this fuel, which would entail significant costs for development of such units.

Thus, there is an urgent need for widespread deployment of small CHP units for different fuels. This was the aim of "KROPAT" project - development and production of such equipment, as well as promotion of cogeneration, energy efficiency and energy saving in society.